Mining

Transforming Mining Through Automation, Insight, and Innovation

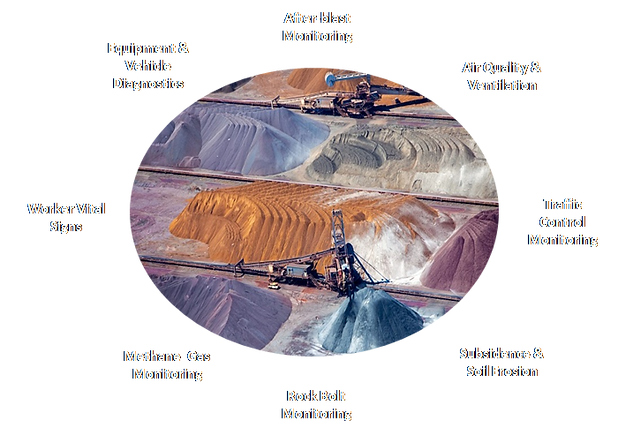

The mining industry faces rising costs, declining ore grades, and increasing pressure for safety and sustainability. With aging infrastructure and remote sites, efficiency and visibility are essential. To stay competitive, operators must embrace IIoT, automation, and real-time analytics to optimize performance and reduce downtime.

Zotera delivers automation, safety, and real-time insight across vehicles, equipment, and facilities. Through asset tracking and predictive maintenance, operators can anticipate issues, prevent downtime, and enhance overall performance.

A significant share of mining costs comes from accidents and maintenance. Equipment in open-pit, surface, or underground mines can be equipped with IoT sensors and wireless transmitters to improve safety and monitor machine performance more accurately.

Trucks and equipment with GPS and performance sensors can share real-time location and operating data to prevent collisions and improve coordination. Analyzing this data enables operators to move from reactive or preventive maintenance to predictive maintenance.